ALIBERICO GROUP GENERAL CONDITIONS OF SALE

Article 1: Application and enforceability of the General Conditions of Sale

These general conditions of sale (hereinafter the “GCS”) are applicable for any and all orders or requests for Product offers (as defined in Article 3 below) received by any of the companies of the ALIBERICO Group of companies (hereinafter “AG” or the “Seller”). The placing of any order or request for an offer of products of AG by any person, whether natural or legal, (hereinafter the “Customer”) represents adhesion, without any reservation whatsoever, to these GCS, and the exclusion of the application of any other terms or conditions that may be contained in any other document issued by the Seller. No particular condition shall prevail over these GCS, nor be enforceable on the Seller unless previously expressly accepted in writing by it. The fact that the Seller does not on any given occasion enforce any of these GCS may not be construed as a waiver by the Seller of subsequent enforcement of any of the said GCS.

Article 2: Availability of the General Conditions of Sale

These GCS will be made available by the Seller prior to entering into the contract between the parties. Furthermore, these GCS are fully available to the Customer on the website of the AG (www.aliberico.com), which can be accessed before contract agreement.

Artícle 3: Products

“Products” refers to the items described in the Particular Conditions (as defined in Article 4 below).

Article 4: Request for offer and order

The Customer, prior to placing an order, must either personally, or by electronic means, or through the sales staff of AG, request an offer from the Seller, specifying the Product needs (types, dimensions, volumes, qualities, etc...). The Customer must provide AG with the identification data necessary to complete the New Customer Form. Once the offer request has been received, the Seller will study it and make an offer to the Customer concerning both the Products and possible financing thereof, the granting of which in any case will be subject to the discretion of AG. This offer will be valid for seven (7) days as of the date of the offer, within which period the Customer must place its order, unless otherwise indicated in the Particular Conditions. Such orders will not be firm until the Customer receives express written notice from the Seller accepting and confirming the order, in the absence of which notice the order is to be deemed rejected. The specific terms and conditions established in the order shall constitute the particular conditions that complement and complete these GCS (hereinafter “Particular Conditions”). In the event of a discrepancy between the GCS and the Particular Conditions, the latter shall prevail over the former, in the terms indicated in article 1 above.

Article 5: Cancellation and/or Modification of the order

Products based on standard material: The cancellation and/or any modification of an order requested by the Customer shall only be effective if made in writing, within seven (7) days after confirmation of the order and shall require the express written agreement of the Seller.

Products based on special material: The cancellation and/or any modification of an order requested by the Customer shall only be effective if accepted expressly by the Seller and/or if the Customer pays all the expenses incurred by the Seller in the purchase and use of specific material for the Customer. To this purpose the Seller may retain payments advanced by the Customer.

Article 6: Forms of delivery of Products

Unless otherwise indicated in the Particular Conditions, the Seller shall comply with its obligation to Products delivery in any of the following cases: (i) by direct delivery to the Customer, (ii) by giving notice of availability (iii) and/or by delivery to a haulage company or professional designated by the Customer at the Seller’s premises.

In the event of notice of availability, the Customer must withdraw the products within fifteen (15) days after receiving notice. At the end of this term, and notwithstanding the actions available to demand performance of the contract, the Seller may consider the order cancelled and the sale unilaterally terminated. The same rule shall be applicable in the event that delivery is to be made at the Seller’s premises to a haulage company or professional designated by the Customer. The Customer shall provide all the material and/or equipment necessary for the delivery of the Products. The Customer will defray all the expenses and costs of locating the Products at the Customer’s premises.

Unless otherwise agreed in the Particular Conditions, the Seller will deliver the Products packaged according to its procedures. In the event that the Customer wishes delivery to be made to the Seller’s premises, checking and verifying the Products there, the Customer must notify the Seller of this fact on the order or in the request of offer document. In this case, the Products will be verified following the Seller’s procedures, and the Customer must defray the expenses this causes.

Article 7: Delivery term

The delivery term for the Products will be as specified in the Particular Conditions. The Seller may make partial deliveries. The delivery terms are approximate and not binding on the Seller. Failure to comply therewith shall not generate any obligation to compensate whatsoever and shall not entitle the Customer to withhold any amounts owing to the Seller, nor to cancel any outstanding orders. However, unless there is a cause of force majeure, if two months after the indicated delivery date the Product has not been delivered, the sale may be terminated by either of the Parties, and the Customer may obtain reimbursement of any advance payments made, excluding any compensation. The following are considered cases of force majeure: war, mutiny, fire, strikes, accidents and the impossibility for the Seller of receiving supplies not attributable to the Seller. The Seller shall inform the Customer in a timely manner of the cases and events listed above.

Unless otherwise established in the Particular Conditions, the delivery term shall start to run on the date of receipt by the Seller of the first payment by the Customer for the Products, according to article 12 below.

Article 8: Undertaking of risks in the delivery of Products

In the absence of any indication to the contrary in the Particular Conditions, the Products sold will be supplied by the Seller carriage due at the agreed place.

If the transportation has been undertaken by the Seller in the Particular Conditions, the Seller shall accept the risk for damage or deterioration of the Products during transport, although in order to enforce the Seller’s liability, the Customer must state the apparent defects, as a result of transportation, on the delivery note issued by the hauler upon delivery and the Seller, at the same time, by faxing a copy of the said delivery note. Otherwise the Seller shall not accept any liability whatsoever for damage caused to the Products during transport.

The Customer must, within the term of thirty (30) days after receiving the order, carry out all the necessary verifications and make any complaints to the Seller in relation to the Products delivered, by any mean that ensures that the Seller is aware of the Customer’s dissatisfaction and justifying the reasons for the claim. The Customer must provide the Seller with access to the places necessary to check the facts claimed. The Customer must also refrain from intervening or causing the intervention of a third party for these purposes. As regards Products sold in packaged form, the weight and measurements of each package on leaving the warehouse will be sufficient evidence of the quantities delivered.

Article 9: Return of Products or reimbursement of the price

In the event of disagreement with the Products delivered, reported to the Seller in accordance with Article 8 above, the Customer may, at the Seller’s option, obtain a replacement, in which case the Customer shall defray the expenses and risks of such a return, or reimbursement of the price paid for the Products, in which case the Seller’s liability shall be limited to the amount of the price paid by the Customer. In either of these cases, the Customer’s right to any compensation is excluded, in particular, for consequential damages and for any damages caused to the Customer as a result of loss of production, impossibility and/or delay in carrying on the Customers’ business activity or that of third parties related to the Customer.

In any case, the Seller’s liability is excluded in the following cases:

(i) if the damage is the result of intervention or handling of the Products carried out without the Seller’s authorization;

(ii) if the dissatisfaction is due to a factor unrelated to the Product, in particular but not solely, to the environmental conditions of the Customer’s establishment or the conditions of the Customer’s material to which the Product is incorporated;

(iii) if the dissatisfaction is the result of the normal wear and tear of the Product or negligence or lack of maintenance by the Customer; and/or (iv) if it is the result of a circumstance of force majeure.

Article 10: Price

The prices offered by the Seller do not include VAT or any type of indirect tax, and the amount and form of payment thereof shall be determined in the Particular Conditions. Any tax, tariff, dues or other charge payable in accordance with Spanish legislation or the legislation of the country of destination of the Products or a transit country, shall be defrayed by the Customer. Any costs and expenses of transport, assembly and insurance shall be defrayed by the Customer.

Article 11: Invoicing

The Seller shall issue an invoice for each of the deliveries of Products. The date of dispatch of the Products will also be the date of issue of the invoice and the date of reference for payments and other items related to payment. The Customer consents to receive electronic invoices. Notwithstanding the foregoing, the Customer may opt to terminate the electronic invoicing service at any time by submitting a request to this end in writing or by email.

Article 12: Payment

Payment of the price for the Products will be made within thirty (30) days after the invoice date by the means of payment established in the Particular Conditions.

If the Products have been made using special material, the Customer must make an advance payment of 20% of the total price, within the term of fifteen (15) days after confirmation of the order, by paying or transferring the said amount to the bank account indicated by the Seller and specified in the Particular Conditions. The remainder of the price will be paid within thirty (30) days after the invoice date by the means of payment established in the Particular Conditions.

Notwithstanding the above, in the case of first orders by new Customers, the price must be paid in full before the Products are shipped, by paying or transferring the amount to the bank account indicated by the Seller and specified in the Particular Conditions.

The Seller may finance payment of the Products by the Customer. Granting financing to the Customer will be discretionary and must be stated in the Particular Conditions. The Seller will be entitled to review and modify the conditions of such financing in the event of a modification in the economic and financial circumstances of the Customer.

Article 13: Delay or default in payment

If on the due date of a payment obligation, payment is not made, the Seller shall demand payment from the Customer, and may suspend all or part of the Customer’s outstanding orders, notwithstanding any other legal rights to which it is entitled. Furthermore, and as an effect of the default, interest shall start to accrue in favour of the Seller automatically and with no need for notice to the Customer, until payment is made, at a rate which will be established in accordance with Act 3/2004, of 29th December, establishing measures against default in commercial operations. If, within the term of forty-eight (48) hours after the Customer has received a demand for payment, it has not been made, the Seller shall be entitled to terminate this contract and any contracts entered into by the Customer with AG. In this case the Seller shall be entitled to (i) request the return of the Products sold, notwithstanding its right to compensation for any damages suffered, and (ii) if payment had been deferred, the Seller shall be entitled to demand immediate payment of the total price. The Seller may also terminate all or part of the sales of the Customer in question or of any entity of the Company’s group of companies or in which the Customer has a stake. In the event that the Seller opts not to terminate the remaining sales, all amounts owing by the Customer in respect of such other orders or for any other cause shall be payable immediately. Furthermore, the Customer shall reimburse the Seller for the expenses incurred in recovering in court the amounts owed and the legal costs, including the professional fees of Notaries Public, lawyers and court representatives.

Article 14: Retention of title

The Seller shall retain title to the Products sold until payment of the total price has been made, plus interest and expenses. The failure to pay on any due date shall entitle the Seller to reclaim the Products sold. The Customer undertakes to communicate the existence of this retention of title clause to any third party wishing to acquire the Customer’s Products.

Throughout the validity of the retention of title clause, the Customer undertakes to maintain and conserve the Products in good condition for the purpose for which they are intended, at its cost, and to maintain the labels or other material used to identify the Seller’s ownership of the Products.

In the event that the Customer breaches its obligation to pay the price, interest and expenses to the Seller in the term stipulated to that end, the Seller shall notify the Customer of this fact, indicating the date and time of collection of the Products from the Customer’s warehouse, or, at the Seller’s option, to claim free dispatch of the Products to the Seller’s warehouse.

If the Customer has transferred ownership of the Products to a third party, or if as a result of any circumstance a third party has become the owner of the Products, the Customer shall assign to the Seller, upon the Seller’s request, the actions in its favour against any such third party.

Article 15: Industrial and intellectual property rights

Any patents, trademarks, trade names and other intellectual property rights, including, without limitation, all reproduction rights on the Products sold, and on plans, notes or specifications prepared by the Seller are the property of the Seller. No document delivered by the Seller may be copied or delivered to third parties without its prior consent, and must be returned to the Seller when it claims them. The Customer undertakes not to erase from the Products, materials or documents delivered by the Seller, the trademark or patent reference or registration concerning the reproduction right or any other registration or symbol relating to the existence of any industrial and/or intellectual property rights.

Article 16: Offset

By application of article 1195 of the Civil Code, any amount owed by the Customer to the Seller and not paid on the established due date, shall be offset with any amounts the Seller owes the Customer in relation to other orders, provided that the Seller has given its prior written consent.

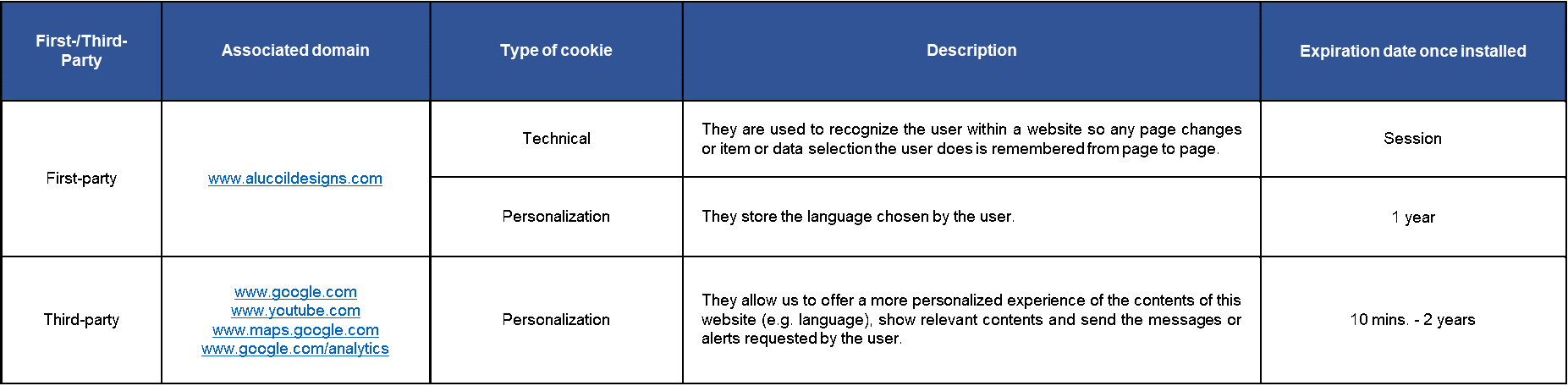

Article 17: Personal data protection

The Privacy Policy is available on the website of the Seller with whom the Customer is trading.

Article 18: Confidentiality

The Customer undertakes to keep strictly confidential any information that has been supplied to it by AG, unless it was or becomes public knowledge, and not to convey it in full or in part to any natural or legal person, other than its direct executives or employees or those of its subsidiaries, or its external advisers.

Article 19: Applicable law and jurisdiction

These General Conditions shall be governed and construed in accordance with common Spanish legislation. For any disputes arising in relation to the interpretation, performance, rescission or termination of the General Conditions, the Parties submit to the jurisdiction of the Judges and Courts of the city of Madrid.

Notwithstanding the above, in accordance with Spanish legislation, for all matters arising in relation to these General Conditions, the judges and Courts of the applicable domicile shall be competent, in accordance with article 52 of the Civil Procedures Act or other substantive regulation applicable from time to time. The Customer states that is aware of the entire contents of these GCS and adheres thereto, which become an integral part of the contract binding the Customer and the Seller.